We have developed the marine biodegradable bio-composite plastic material “BiofadeTM” with the aim of solving the world’s marine plastic waste problem.

What is “biodegradable plastic”?

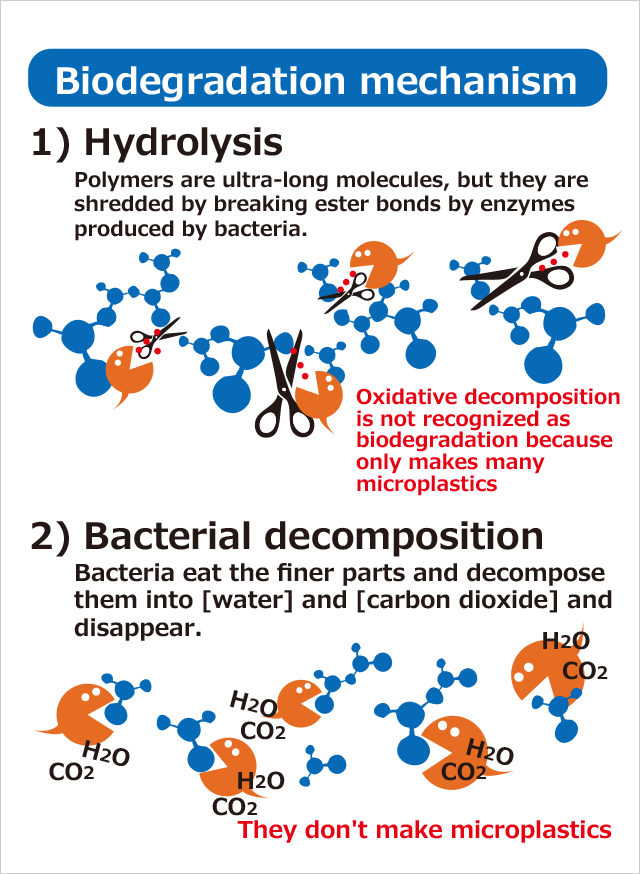

Many common plastics, such as polyethylene and polypropylene, do not biodegrade, but some few types of polyester resins biodegrade. These biodegradable plastics decompose under conditions such as water and enzymes produced by microorganisms. This is called the first stage hydrolysis. The plastic, which is then shortened by hydrolysis, is eaten by, for example, bacterial microorganisms that live in the soil or water, and is decomposed into water and carbon dioxide, after which nothing is left. This is the second stage of biodegradation.

Biodegradable plastics are eventually completely decomposed by bacteria, but they are safer because they are microplastics for a relatively short period of time. Also, if there is biomass such as wood flour or starch together, it will eventually be decomposed by bacteria as well. By making good use of these, for example, in soil, lake water, or seawater, it is possible to make plastic materials that biodegrade without making microplastics.

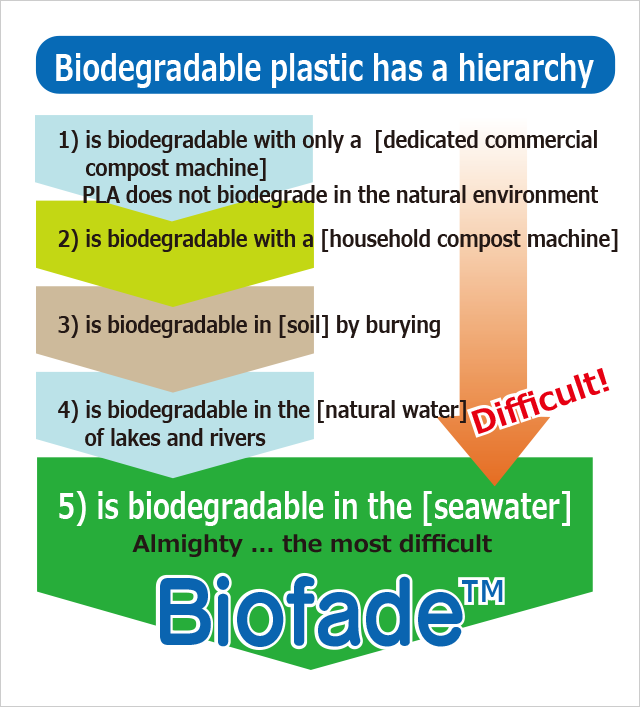

There are various types of “biodegradable plastics”

The amount of bacteria varies depending on the environment in which the biodegradable plastic is placed. For example, in an environment where a large amount of bacteria inhabits, such as in garbage and soil, biodegradation is relatively easy to proceed, but in seawater, there are very few bacteria, so it can be said that it is a very difficult environment for biodegradation. Conversely, plastics that biodegrade in seawater can be said to biodegrade almighty in any other environment.

In order to solve the plastic waste problem including the “sea plastic waste problem”, we aimed for a plastic material that easily biodegrades even in seawater. The result is “Biofade”. This was made in collaboration with the Tokyo Metropolitan Industrial Technology Research Institute.

What are the features of “Biofade”?

➀ High degree of biodegradation ⇨ ⇨ Biodegradation is easy to proceed

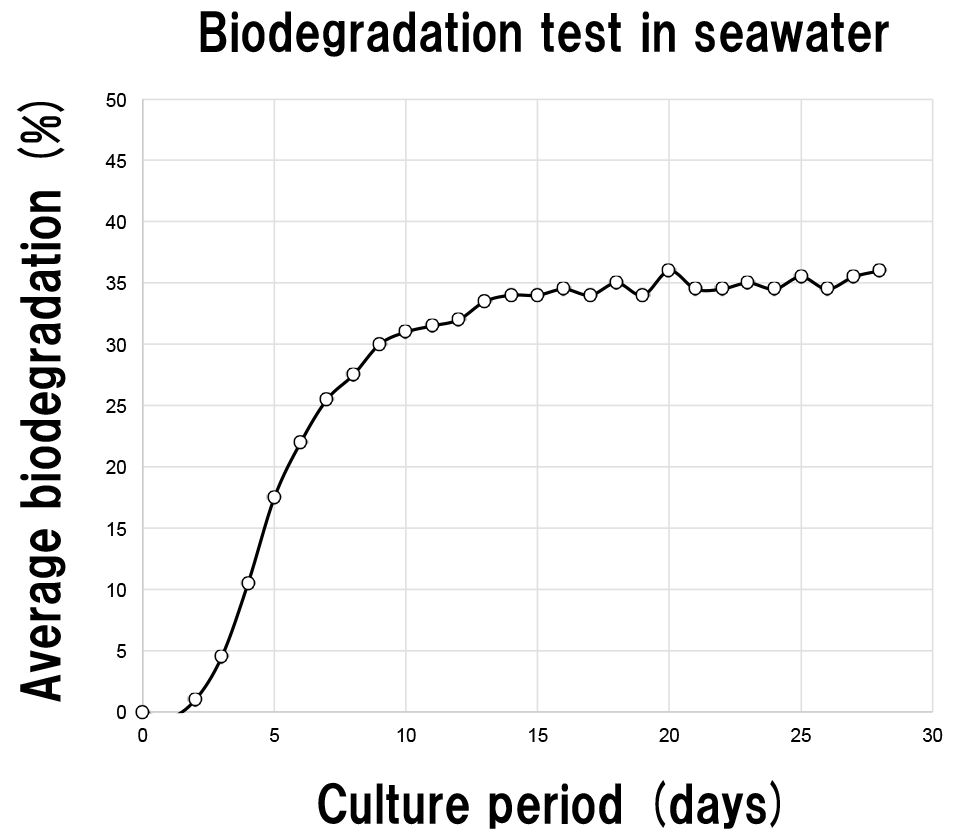

The test to confirm the biodegradability in seawater (modified method of ASTM D6691) was carried out by the “Chemicals Evaluation and Research Institute, Japan(CERI)”, which has abundant experience in biodegradability testing. Specifically, the degree of biodegradation is evaluated by putting plastic powder in seawater and measuring the amount of oxygen consumed when the plastic is biodegraded.

As a result, with the 40% wood flour additive, the average biodegradation degree was 36% after 28 days. Lignin, which is a component of wood flour, is biodegraded with a slight delay, so it is thought that the degree of biodegradation will increase if more time is taken. It can be said that it is a material that biodegrades sufficiently in seawater.

In addition, although it is not evaluated side by side and it can not be said that it is superior or inferior only during this period, the published value of PHBH, which is very famous for marine biodegradable plastic, was 23% biodegradation under the same conditions. So, looking only at the numbers, the result was about 13% better.

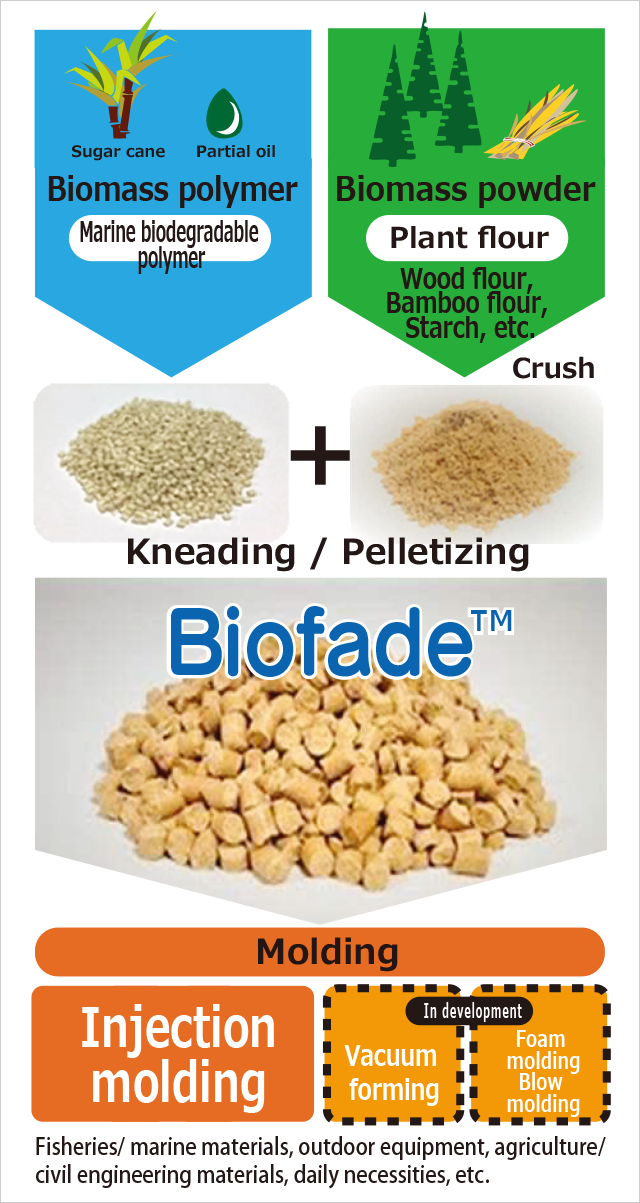

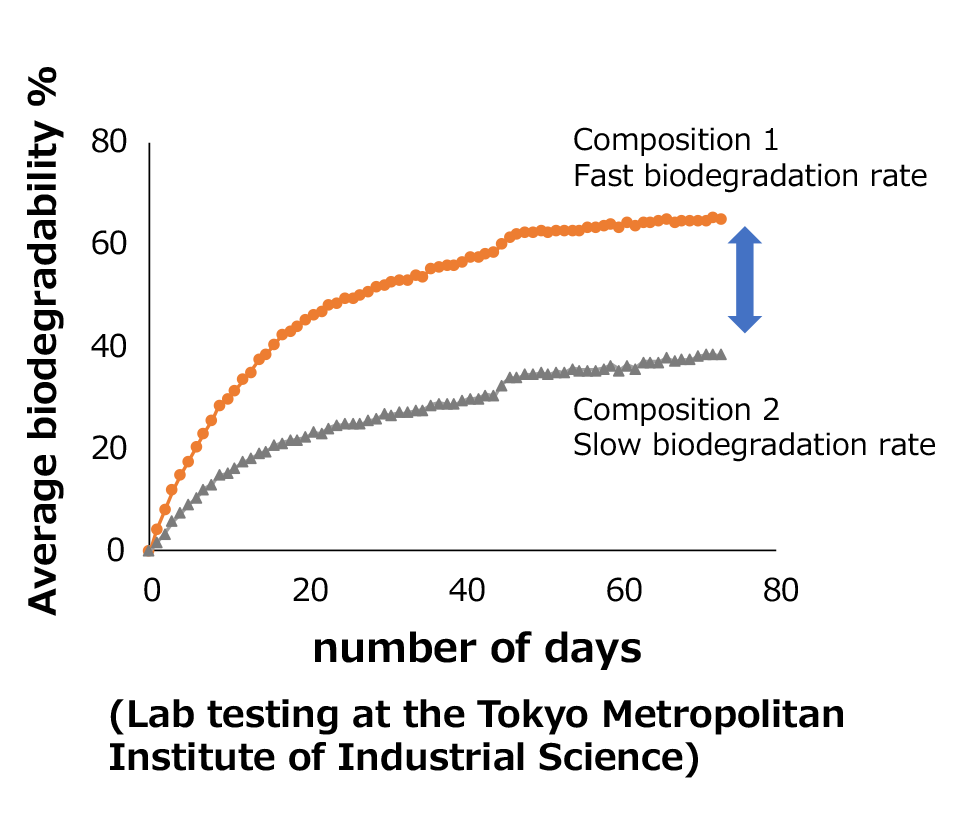

Furthermore, as shown in the figure on the right above, by changing the composition of the raw material biomass polymers, the ratio of the types, and the ratio of the biomass powder, we can create products with fast or slow biodegradation rates. We can also create compositions with even faster biodegradation rates.

For example, we want to use floats in the ocean for several years. We want them to develop holes and slowly biodegrade on the ocean floor over several years. On the other hand, it’s better for blow bottles to biodegrade quickly.

Furthermore, we have found that the melt properties of products suitable for injection molding and blow molding can be created by changing the raw material composition. In other words, Biofade is versatile.

You can choose the biodegradation performance and molding depending on the product you are making.

② Easy to injection mold

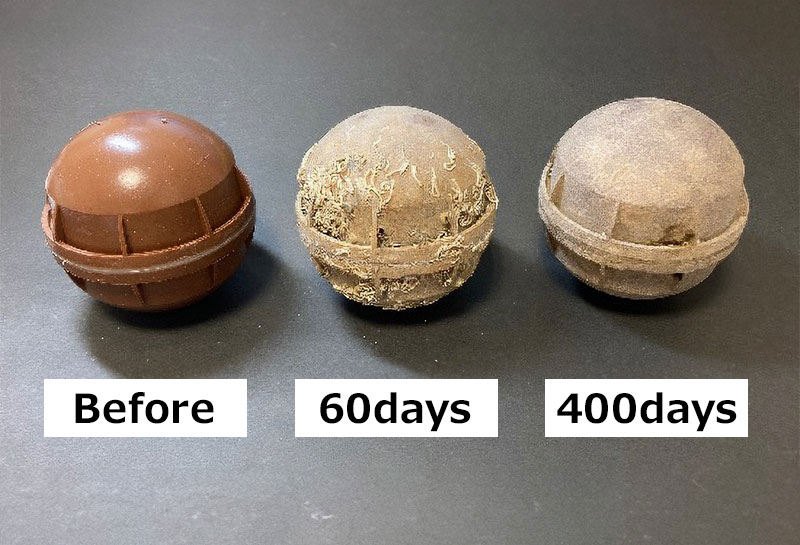

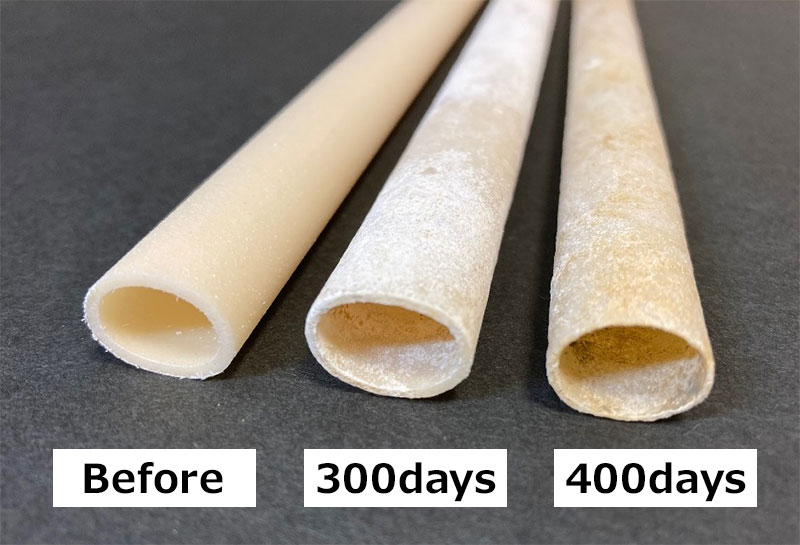

Biomass composite plastic can be injection molded, so it can be made in various shapes. Even if it is blown away by the wind and enters a river and flows into the sea, it will not become plastic waste in the sea as it will eventually be cleaned by bacteria over time.

This type of plastic is a crystalline resin, but it is necessary for molding that it is easy to crystallize, that is, it hardens quickly when cooled from a high molding temperature. As a result of examining the crystallization behavior by DSC measurement, it was found that the crystallization was pretty fast. The photo above is an example of a spoon or toothbrush made by injection molding.

I had an idea to make such a product, how about this usage, please feel free to contact us. It would be great if it could be widely used and the “sea plastic waste problem” could be improved as much as possible.

Examples of Biofade’s social implementation

① Drifting buoy for ocean current surveys

(Provided by ZENI LITE BUOY Co., Ltd.)

Warm currents flow into Japan from the East China Sea, the Kuroshio Current flows into the Pacific Ocean. And the Tsushima Current flows into the Sea of Japan, and cold currents flow from the north to form the Liman Current. Ocean currents follow complex routes and collide with each other, creating good fishing grounds. But in recent years, it seems that ocean currents have become difficult to read due to global warming and other factors. Ocean current surveys are necessary to study how newborn juvenile fish flow and grow, and in rare cases, to estimate the flow of pumice from undersea volcanic eruptions.

ZENI LITE BUOY Co., Ltd. has developed a small drifting buoy with built-in GPS using our marine biodegradable plastic material. In previous drifting buoy surveys, the buoys were made of reinforced plastic, so they would eventually become marine garbage somewhere almost forever, making it a disappointing ocean current survey.

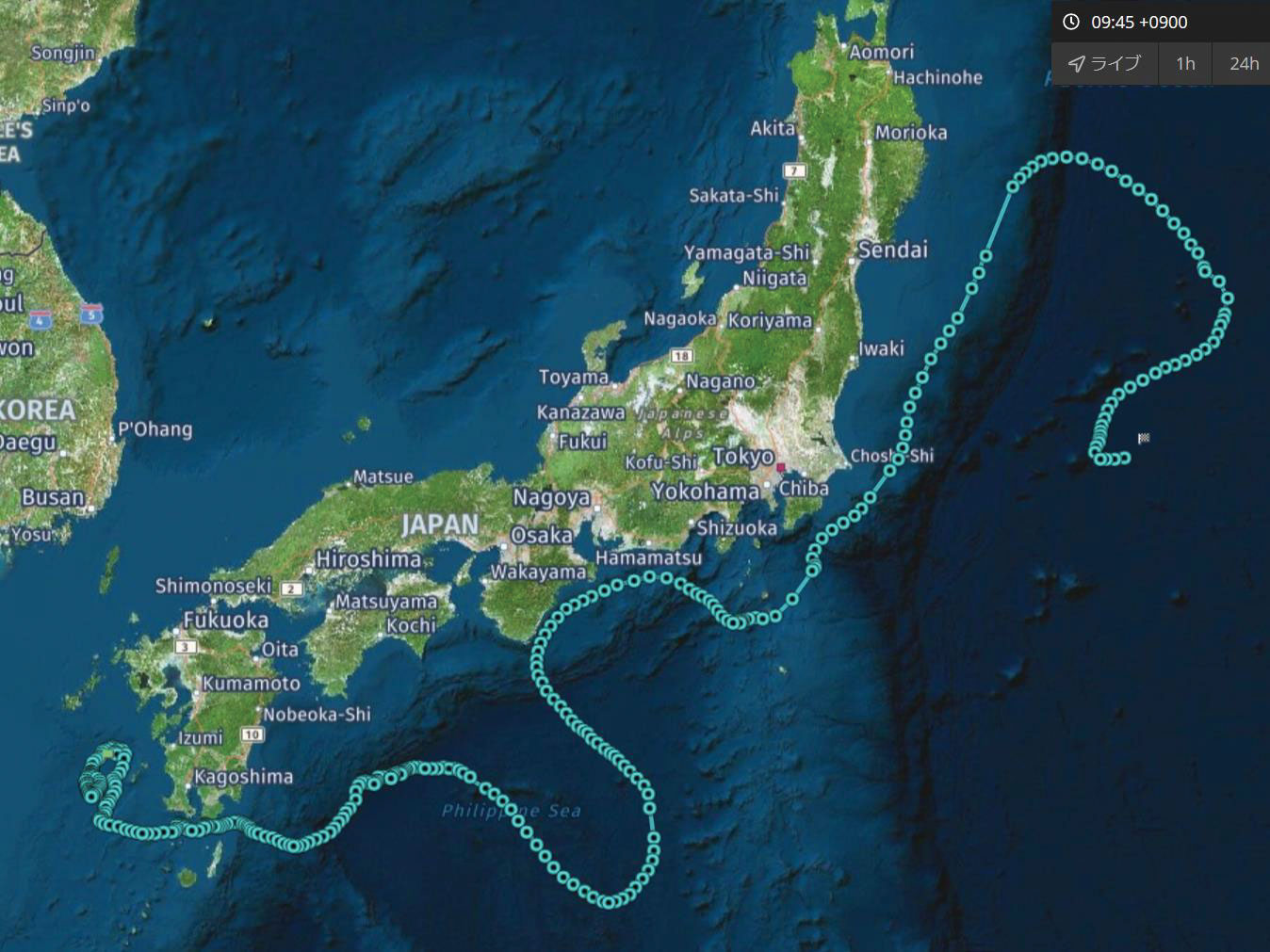

In a survey conducted by Atmosphere and Ocean Research Institute, The University of Tokyo in 2023, more than a dozen buoys were released in the East China Sea and drifted across a wide area of the Sea of Japan and the Pacific Ocean, enduring the high waves of a typhoon along the way and collecting a lot of data. One of these buoys, which drifted into the Pacific Ocean, was the first to successfully measure the “Great Meander of the Kuroshio Current,” an ocean current estimated by JAMSTEC from seawater temperature in recent years. The “Great Meander of the Kuroshio Current” irregularly travels several hundred kilometers south off the coast of Shikoku and the Kii Peninsula, makes a U-turn, and then travels north from the Kii Peninsula to the Sanriku coast.

Survey equipment such as drifting buoys made from marine biodegradable plastic materials will eventually biodegrade on the seabed after a few years and will not become marine debris. So they should be a welcome addition to marine researchers. Of course, if it is used for fishing gear that is destined to end up in the ocean, it should be possible to significantly reduce the amount of plastic waste in the ocean. It is said that about half of the world’s marine plastic waste is fishing gear.

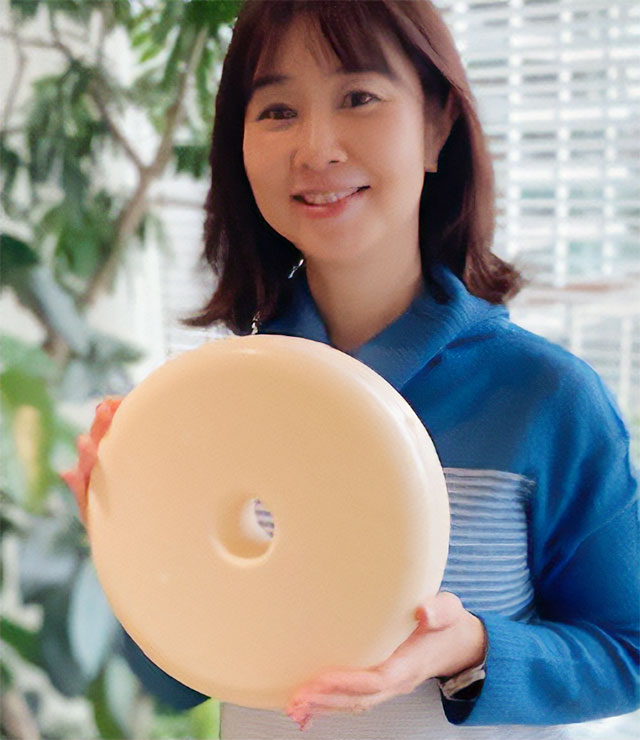

In 2024, we tested an improved drifting buoy using what is probably the world’s first blow-molded “25cm diameter ring float” made from marine biodegradable plastic, and obtained good results.